I received this engine as a gift in a sorry state; it had been in a really hot fire and was quite rusty.

All the bearings had melted out and the resulting ingot was in the bottom of the case/frame (I made bearings from phosphor bronze).

The piston was well seized and resisted a couple of weeks on end with a half an inch of paraffin on top of the piston (resorted to a piece of two by two and a large hammer).

I had to work on the crank and flywheels as an assembly (very inhibitive) as the wedges that hold the flywheels on the crank had been made of something more like cast that good quality steel and broke at every attempt, I welded the lug back on more than once and used a lot of heat but finally surrendered.

All springs were also rusty and collapsed with the heat Iím still experimenting with spring tensions to get it to run correct (if anyone knows where I can get springs for this please mail me.

I had rather a bad accident with the atmospheric inlet valve whilst I was running one test whereby I managed to cause the valve to drop its retainer pin and get sucked into the engine, I thought Iíd destroyed it but although it obviously annihilated the valve no damage was done to piston or head these things are hard, I made a new valve using EN24T steel.

There was no mag or mount with the engine but my sisterís boy friend came up with two Wico EKís from which I made one good one (made trigger by utilizing reciprocating saw blades as spring steel couldnít be obtained) I also made a mounting bracket.

I had the paint made by Apec paints (Norwich).

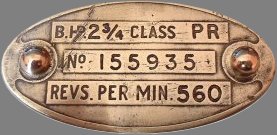

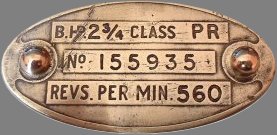

Decals, blue print and techí info was supplied by Ray Hooley.

Fuel tank had suffered badly the solder obviously had all gone, filler neck had also gone as had the none-return valve, I repaired the tank making new filler neck, valve and filler cap.

Iíve made an exhaust extension to reduce the bark as although my neighbours are very understanding and never complain I think some consideration would come amiss.

The first trolley I made from scratch including the wheels was rather small for this engine so I made another using wheels I purchased from a chap at the Strumpshaw 2006 Rally.

Update

It ran at Henham rally for the Saturday then no more apart from firing up and dying after getting flooded no matter how much I turned the fuel valve off.

I have to confess everyone who has commented on this has immediately questioned the mag, however! Bearing in mind that all the internals of my EK are new, it had a fat spark when a plug was tried on the lead and mostly the fact that itíd fire up and one would think that if itíd do that then it has a spark in side.

Not so! I fashioned a make shift spark gap to fit into the lead to watch the spark, it consisted of a short piece of clear tube that would fit tightly onto the HT lead, I then pushed the lead ends with a little bare wire protruding into the tube and left approx. 20 thou gap.

Turning the engine with the inlet valve open the gap was sparking merrily without compression, as soon as I released the inlet valve and when the cylinder came under pressure the spark (needing to jump both spark and plug gap) failed.

Still sceptical I borrowed an EK from a open crank Bamford 5hp hit & miss that was in my sisters boy friendís garage (belongs to his mate), it fired up and ran for two hours until it ran out of petrol (havenít gone near paraffin yet).

Update

I have now been able to make fine adjustments to the throttle governor and air intake plate springs, I also found once it was running for some time that the exhaust valve spring was not strong enough, this was allowing the valve to flutter slightly as the atmospheric inlet valve does (not helping matters in the slightest).

Engine now runs marvellously even when switched over to the rubbish paraffin you get from local stores (providing you get it quite warm on petrol first).

Update

Engine is complete the odd touch up or improvement may happen but itís basically done.

Latest addition was a brass trim I made for the hopper filling hole, ran in the rain all day at Strumpshaw 07.